Working with a buffer

According to the Critical Chain Project Management method, fifty percent of the built-in safety margins in project planning can go. It is a waste of time. So by taking this out, we can carry out projects in three-quarters of the time. That is a time saving of 25 percent. To achieve this, the method uses Buffer Management technology.

The Critical Chain Project Management method has never gained much popularity. But it offers an interesting view. It looks at project planning in a radically different way. In this blog, we will discuss the causes of waste of time, how Buffer Management works and how you can apply this in your project planning.

We estimate the margin too broadly

I have already discussed the causes of waste of time in the blog ‘4 time wasters in project planning’. It’s about Student Syndrome and Parkinson’s Law. These ensure that employees estimate (too) large of a safety margin in their project planning for their activities and waste it completely.

As a rule, it appears that we estimate twice as much time to complete an activity as we need because we want to cover ourselves.

This is deeply rooted psychologically and culturally because:

- We experience late delivery as a loss of face.

- We will not be rewarded if we deliver earlier.

Giving up individual safety margins in project planning

Critical Chain Project Management states that employees must give up their margins in project planning. This is where the greatest resistance lies, because people want to perform well. With their own safety margin it works best. But you have to get rid of this. All employees must no longer think about their own interests, but about the collective interest.

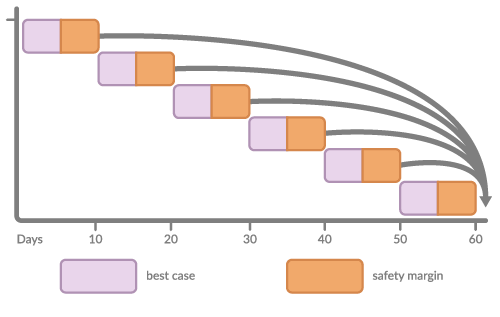

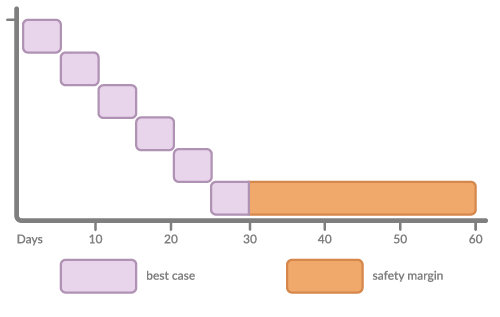

All individual safety margins are bundled in one large safety margin at the end of the project. Critical Chain Project Management calls this a buffer.

An important change is that people must accept uncertainty. There must be a culture where it is ‘ok‘ if you don’t make it according to the planning. It is even likely that it will take you longer. This is not a problem, because the project has one large buffer in which we will catch that.

Making a realistic buffer

By bundling all individual safety margins in project planning at the end of the project, you immediately see how disproportionate the safety margins are compared to the activities to be carried out. The buffer must be brought into proportion.

Critical Chain Project Management says there is a good chance that an activity lasts fifty percent longer than estimated. This is normal. By reducing the buffer according to this rule, you reduce the total duration by a quarter. In other words, a time saving of 25 percent!

One of the key tasks of the project manager is managing the buffer. The buffer is used up during the project. The project manager must ensure that the buffer is not used up too quickly. Otherwise, there is a chance that the project does not meet the deadline. If the buffer is used disproportionately, the project manager must adjust it accordingly.

How can you do this in practice?

Please note: here now follows a shameless promotion of our product (but it is of course also possible in another package).

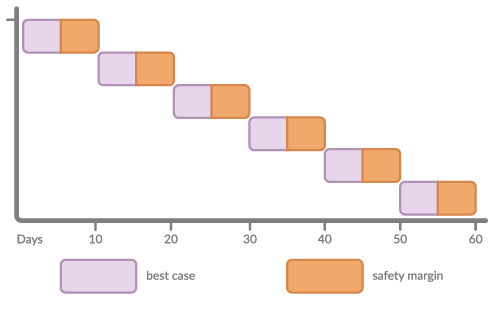

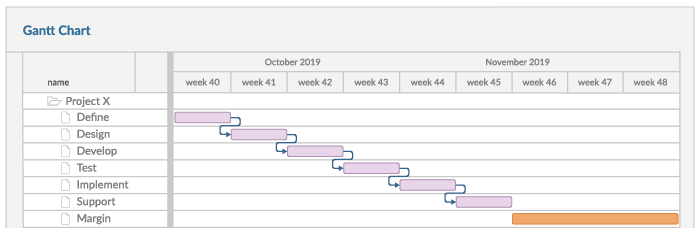

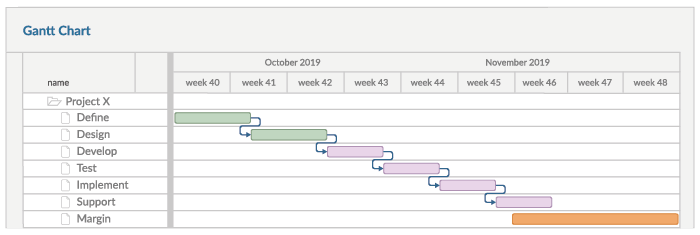

I made a ‘Baseline‘ version of the project planning in the Gantt Chart feature of Timewax. All activities are consecutive, with the exception of the buffer. Because it has a fixed start and end date.

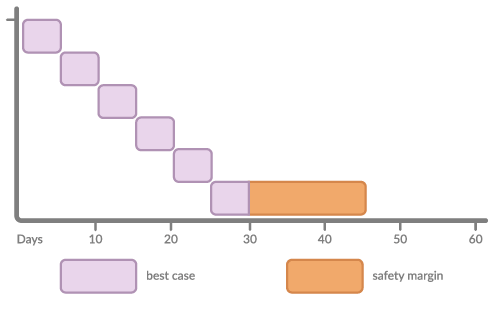

I have made a new version that shows the status of the project planning below. The project planning has been updated based on the time it took to complete the ‘Define‘ and ‘Design‘ activities.

More time was needed for both activities (fifty percent). You now see that the total chain extends to one-third of the buffer. That is no problem because the buffer also contains the extra time that is reserved for these first two activities.

Conclusion

But why is Critical Chain Project Management not a worldwide success? And why is it not the standard for project planning? My opinion:

- The method is a totalitarian approach. You have to handle it with your entire organisation, otherwise it won’t work.

- It often conflicts with the unwritten law of project management methods used.

- It does not work well in environments where a lot of multitasking takes place because it requires dedicated resources.

- The method has achieved many successes in industrial companies, but relatively few in service providers.

Nevertheless, the method shows how much time we waste. In addition, I find the central monitoring of one buffer with all the safety margins of project planning very valuable. This works much better than when we leave this to the individual employee. Nothing to the detriment of their capacities, but the collective interest is simply better represented.